Source – https://innovationorigins.com/

Fraunhofer Institute scientists have developed quality control software that allows users without expert AI knowledge to benefit from AI.

Although they can bring great benefits in everyday work, many small and medium-sized enterprises (SMEs) shy away from applications based on artificial intelligence. But AI offers a lot of potential, especially in quality control. Nevertheless, training the models is difficult and hardly feasible without mathematical knowledge, as there are countless parameters that can go into such an analysis. And once an AI algorithm is learned, it is trained only on the specifications it learns. If a product design or the geometry of a component is later changed even slightly, the algorithm recognizes this as an error and the AI must be retrained.

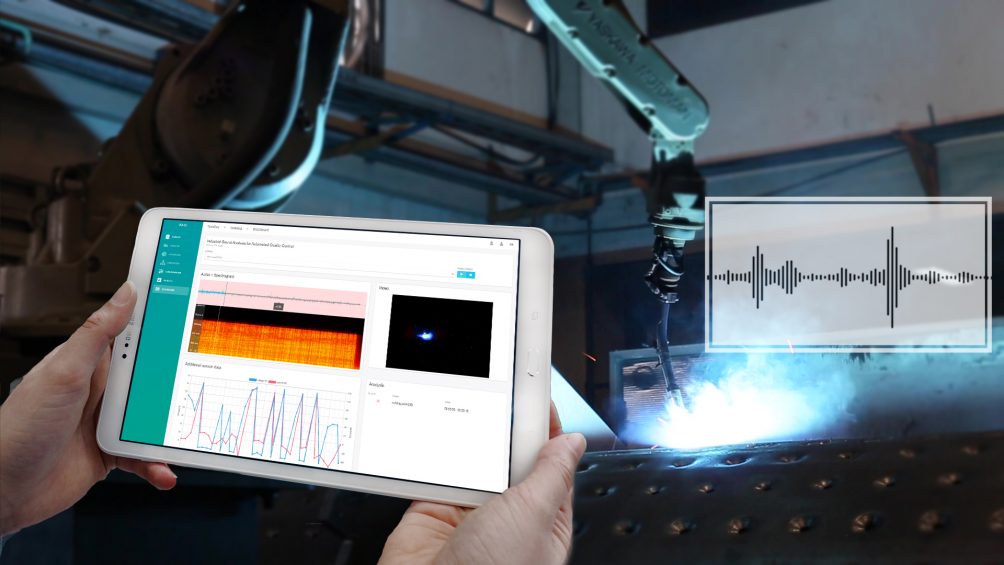

Researchers at the Fraunhofer Institute for Digital Media Technology IDMT in Ilmenau, Germany, have now developed the “IDMT-ISAAC” software, which can be operated even without extensive expert AI knowledge. IDMT-ISAAC stands for Industrial Sound Analysis for Automated Quality Control. “We want to enable SMEs to adapt and customize AI algorithms themselves,” says Judith Liebetrau, group leader of Industrial Media Applications at Fraunhofer IDMT. “They can apply IDMT-ISAAC to their own audio data, retrain it, and thus get fast and reliable results and decision support for their quality assurance.”

Using AI even without expert knowledge

IDMT-ISAAC relies on acoustics for analysis, since in many cases it is possible to detect defects just by the sound of the process. To train the AI, the scientists use recorded acoustic data from welding processes. The AI analyzes the typical noises that occur and draws conclusions about the quality of the respective weld seam from the audio data. If, for example, the geometry of a product is then changed, the user can teach this to IDMT-ISAAC with just a few clicks. As early as summer 2021, the software should be adapted to live operation to the extent that the system can immediately analyze real-time data from production and optimize quality assurance. In three to four years, it should even be able to actively intervene in production.

But the framework at the heart of IDMT-ISAAC doesn’t offer new analysis options just for welding. “We have integrated various methods in the modular system to be able to map other processes, such as milling, relatively quickly,” Liebetrau explains. Companies that already have their own software should also be able to use it in the future. They will also be able to access the institute’s AI via an interface on the Fraunhofer IDMT server. It is important to the developers here to emphasize that data protection and data security would always be observed and that the data would be processed anonymously, regardless of whether companies access the AI via an interface or it is integrated into the company via the framework.

Making AI comprehensible

For different user groups – AI novices as well as AI experts – the software can be customized via different user profiles. For example, developers of AI algorithms are very interested in getting a feel for how AI makes its decisions and the sounds it uses to make them, says Judith Liebetrau. “So we are also moving a bit in the direction of Explainable AI with the framework to make AI more comprehensible,” Liebetrau says.

The researchers will present IDMT-ISAAC at the Hannover Messe from April 12 to 16, 2021. At the virtual booth, Bescher will apply artificial intelligence models using the IDMT-ISAAC software to industrial audio data to verify its quality.