Source – https://metrology.news/

Artificial Intelligence (AI) can be used in many way: for data processing, analytics, combinatory methods, …

AI is a concept that stretches over any possible application field. In the field of automated inspection, there are some basic concepts that can be applied to accelerate and improve the process. For inspection purposes, it is possible to use Artificial Intelligence to detect cracks or dents in the workpiece automatically, which could take a human worker up to hours to inspect, while trying not to lose focus on the task. For this process, the concepts of classification and localization in AI can be used to ensure the function of this inspection system. Classification in this case means, that the AI can classify incoming surface data as intact or as different types of damages. The more different ‚damage‘ classes the AI learns, the more different cracks, dents, shape deformations and other damages, the system can detect. For this classification to function properly, the AI has to be taught many different shapes and damage types to learn every possible facet of a certain crack or dent to learn the fundamental features of a damage in order to distinguish between an intact or damaged object. This process is called ‘machine learning‘. Many different surface data measurements of damages have to be taught to the AI, for it to learn this classification behaviour in completion. There can always be more data to be gathered, because the more data the AI knows, the more certain it can classify these damage types.

The other principle used is the concept of localization. This means, that the AI is able to detect its known damage types inside of a large 2D image. The AI has to learn, how to detect the damages in visual surface data or 2D projections of point clouds that are given to the AI program by the different measuring methods. If the data comes from either White Light Interferometry – a high precision 3D surface inspection method – or visual camera data, the AI can detect and show the position of damages on a connected screen. By combining these two concepts, the AI for inspection purposes can localize and classify any taught damage that occurs on the workpieces surface.

For a little extra usability, an AI can also be taught how to read texts on product labels via Optical Character Recognition. With this feature, all the information from the product label, like serial numbers and product names can be processed and digitalized together with the inspection data. 3D.aero has created a specialized neural network, that doesn’t only allow to read printed labels, but that can also process texts in any form on any surface. Whether it is handwritten, punched or milled in, the AI can read and digitalize each character correctly.

3D.aero use these advanced AI concepts to optimize the inspection and production processes in the aviation industry. 3D.aero expertise lies within the application of these systems to aviation parts and the usability within the hangar workspace.

3D.aero uses Artificial Intelligence for its robot based AutoInspect system. The AutoInspect system provides crack detection in µm-resolution which is used for stationary inspection of aero engine parts. The AI can also be used for the interactive Cobots, where robots work together with human workers on the shop floor where it is very important to have an integrated live tracking system of movement, so that the robot can interact with its surroundings in synchronization. If that would not be the case, the robot could hurt nearby workers or damage the workpiece by not adjusting to sudden movements.

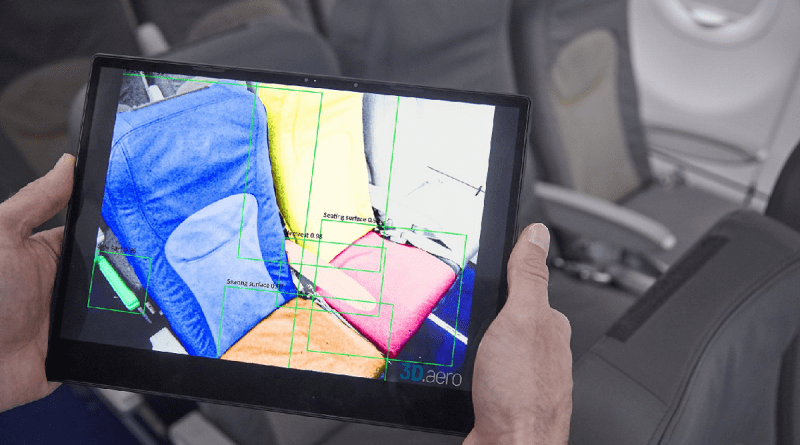

The newest innovative usage of AI at 3D.aero, is their AI2Go system where the process of damage detection and classification can be managed on an edge device such as a tablet or mobile phone. This mobilizes the process and makes it possible for a worker, who is already equipped with a mobile device, to assess anomalies in places that are not reachable for any shop floor robots.

3D.aero has developed the expertise to use AI in the aviation industry, while being able to use the technology on almost any device. Either mobile or stationary, the 3D.aero approach to using AI for inspection purposes in damage detection and classification enabling a functional system early into the integration process, while constantly increasing the applications capabilities. 3D.aero state however “We don’t let our AI algorithms improve themselves during operation. For technical purposes in general and especially in aviation, reliability is key. Therefore we still require a human expert to assess new training data before updating the system.”