Source – forbes.com

Scientists teamed up to use artificial intelligence to discover new alternatives to steel in record time. As a result, they discovered three new blends to form metallic glass and did this 200 times faster than it has ever been done before.

Metallic glass is essentially an alloy of the future. Normally, a few metals can be mixed together so that the ideal properties of each metal are ‘added’ together to make a ‘super-metal’. Alloys tend to behave and look like metals and their atomic structure consists of rigid geometric patterns. Metallic glass, on the other hand, does not have a rigid geometric pattern, but instead, an atomic structure which is disordered much like that of glass. Consequently, this atomic structure allows the material to be lighter and stronger than today’s steel. Thus, metallic glass is an ideal alternative to steel.

Having said this, metallic glass is relatively new and not all combinations of ingredients to make metallic glass have been tested. Out of millions of possibilities, only a few thousand combinations have been evaluated in the last 50 years and only a handful have been developed for use. Finding a way to predict or model the best combinations is something that is sought for in the world of metallic glass. As a result, a group of scientists led by the Department of Energy’s SLAC National Accelerator Laboratory, the National Institute of Standards and Technology (NIST) and Northwestern University have found a shortcut to discovering the best combinations for the best metallic glass, all with the use of artificial intelligence.

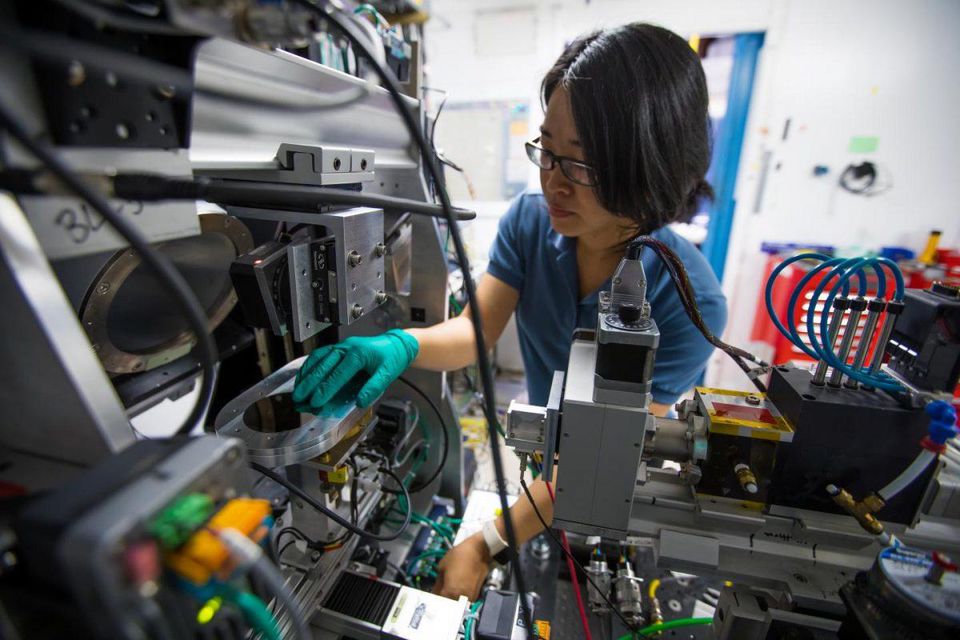

The team used SLAC’s Stanford Synchrotron Radiation Lightsource (SSRL) to discover three new blends of ingredients to form metallic glass via the use of a machine learning system. The findings are reported in Science Advances. Professor Chris Wolverton from Northwestern University and author of the paper says, ‘It typically takes a decade or two to get a material from discovery to commercial use. This is a big step in trying to squeeze that time down. You could start out with nothing more than a list of properties you want in a material and, using AI, quickly narrow the huge field of potential materials to a few good candidates’.

This work cannot only be used for metallic glass but for other materials as well, thus proving to be a very valuable technique for industry. The ultimate goal in the eyes of Professor Wolverton is to get to a point where sample materials could be scanned and machine learning models could offer immediate feedback on the material. In the last half a century, 6000 combinations of ingredients for metallic glass were investigated, but the team were able to make and screen 20,000 with artificial intelligence. The team cycle back and forth between predictions and experimental measurements and results in order to feed vital information into their machine learning system. The SSRL x-ray beam was used to scan the alloys, this data was then fed into the machine learning system, which generated new results and then these were used to create a new sample which was then scanned by the x-ray beam and so on until the best material was made. In the future, this technique is hoped to be faster, automated and used for a myriad of materials. This is just one of many exciting applications of machine learning and artificial intelligence; what a time to be alive.