What is 3D Printing?

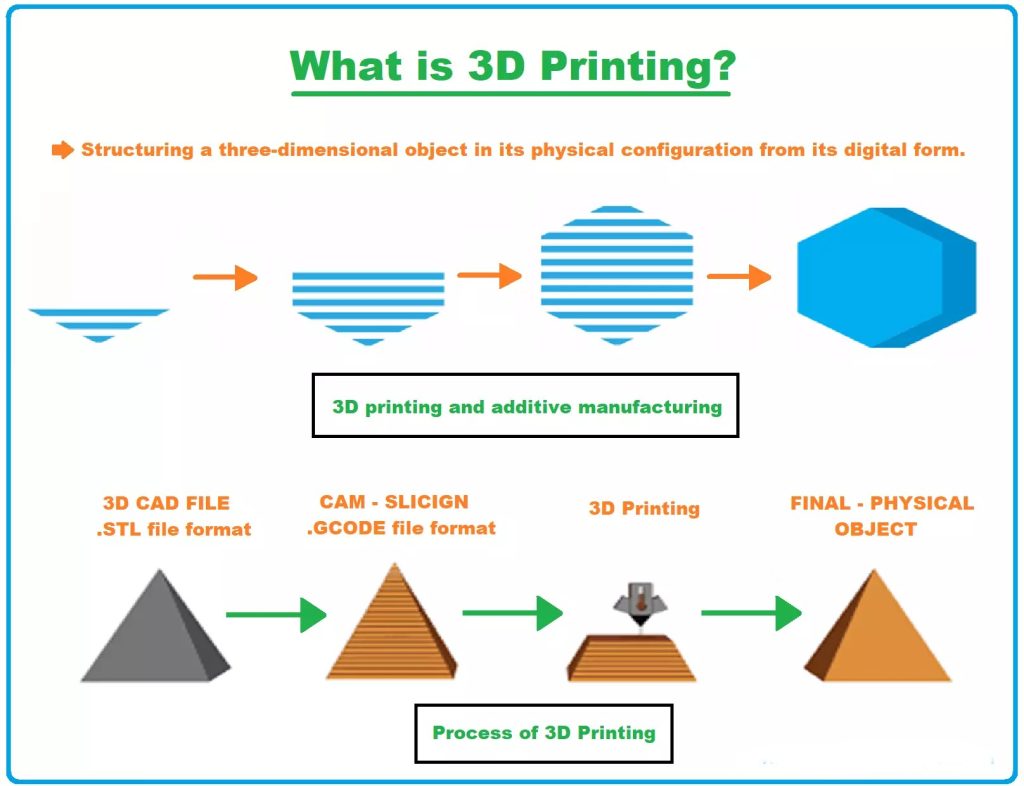

3D printing, also known as additive manufacturing, is the process of creating a physical object from a 3D digital model. This is done by building the object layer by layer, using materials such as plastics, metals, and ceramics. 3D printing allows for the creation of complex and intricate structures that traditional manufacturing methods may not be able to produce.

The History of 3D Printing

The history of 3D printing dates back to the 1980s, when the technology was first developed. However, it wasn’t until the early 2000s that 3D printing became more widely available. Since then, it has been used in a variety of industries, including aerospace, automotive, and healthcare.

Types of 3D Printing Tools and Their Functions

Fused Deposition Modeling (FDM) Printers

FDM printers are the most common type of 3D printer. They work by melting plastic filament and extruding it layer by layer to create the object. FDM printers are relatively inexpensive and can produce durable parts, but they may not be suitable for creating highly detailed or complex structures.

Stereolithography (SLA) Printers

SLA printers use a liquid resin that is hardened by a laser to create the object layer by layer. This method allows for the creation of highly detailed and complex structures, but it can also be more expensive than other 3D printing methods.

Selective Laser Sintering (SLS) Printers

SLS printers use a laser to sinter (i.e. melt and fuse) powdered materials, such as plastics, metals, and ceramics, to create the object layer by layer. SLS printing can produce highly detailed and complex structures, and can be used with a variety of materials. However, it can also be more expensive than other 3D printing methods.

Materials Used in 3D Printing Tools and Their Properties

Plastics

Plastics are one of the most commonly used materials in 3D printing. They come in a variety of types, including ABS, PLA, and nylon, each with their own unique properties such as strength, flexibility, and durability.

Metallic Materials

Metallic materials are often used in 3D printing for their strength and durability. Common metallic materials used in 3D printing include titanium, aluminum, and stainless steel.

Ceramic Materials

Ceramic materials, such as porcelain and zirconia, can be used in 3D printing for creating objects with unique aesthetic and functional properties. Ceramic materials can be difficult to work with, but they can produce highly detailed and durable objects.

Best Practices for Using 3D Printing Tools

Software and Hardware Considerations

When using 3D printing tools, it is important to consider both the software and hardware components. This includes selecting the appropriate 3D modeling software, choosing the right printer and materials, and ensuring that the printer is properly calibrated.

Designing for 3D Printing

Designing for 3D printing requires a different approach than traditional manufacturing methods. It is important to consider factors such as object orientation, support structures, and minimum wall thickness in order to ensure a successful print.

Post-Processing Techniques

After a 3D print is complete, it may require post-processing techniques such as sanding, painting, or polishing in order to achieve the desired finish. It is important to consider these techniques when designing the object and selecting the appropriate materials.

Emerging Trends in 3D Printing Tool Development

The world of 3D printing is constantly evolving, with new and exciting developments emerging all the time. Here are just a few of the most promising trends in 3D printing tool development:

Multi-Material 3D Printing

One of the most exciting recent developments in 3D printing is the ability to print with multiple materials at the same time. This technology allows for the creation of complex, multi-part objects with a variety of properties. For example, a 3D printer could use one material to create a flexible hinge, and another to create a rigid frame. This opens up a wide range of possibilities for designers and manufacturers alike.

Large-Scale 3D Printing

Another trend in 3D printing tool development is the ability to print on a larger scale. While 3D printers have traditionally been limited in size, advances in technology mean that it is now possible to create much larger objects. This has the potential to revolutionize industries such as construction and architecture, where large-scale 3D printing could be used to create everything from walls to entire buildings.

Real-Time, In-Situ Monitoring and Control

Finally, real-time, in-situ monitoring and control is becoming increasingly important in 3D printing. This technology allows for the precise control and adjustment of printing parameters throughout the printing process. For example, a printer could automatically adjust the temperature of the print bed to compensate for changes in room temperature. This ensures that the final product is of the highest quality possible.

Applications and Benefits of 3D Printing Tools

3D printing tools have a wide range of applications across a variety of industries. Here are just a few of the most promising areas where this technology is being used:

Industrial Manufacturing

3D printing is already being used in industrial manufacturing to create everything from prototypes to finished products. This technology can be used to create complex parts that would be difficult or impossible to produce using traditional manufacturing techniques. It also allows for rapid prototyping and iteration, which can help companies bring products to market faster and more efficiently.

Medical and Dental Applications

3D printing is also being used in the medical and dental fields to create custom implants and prosthetics. For example, a 3D printer could be used to create a custom-fitted dental bridge or a prosthetic limb. This technology is also being used to create models of complex medical conditions, which can help doctors plan surgeries and other treatments.

Consumer Products and Accessories

Finally, 3D printing is being used in the consumer products industry to create everything from phone cases to jewelry. This technology allows for the creation of unique, customized products that are tailored to the individual customer. It also allows for rapid prototyping and iteration, which can help designers and manufacturers bring new products to market faster and more efficiently.

Future Prospects of 3D Printing Tools in Various Industries

As 3D printing technology continues to evolve, its potential applications will only continue to expand. Here are just a few of the most promising areas where this technology is likely to have a significant impact in the coming years:

Automotive and Aerospace Industries

The automotive and aerospace industries are both likely to be significantly impacted by 3D printing technology in the coming years. This technology allows for the creation of lightweight, complex parts that can help improve fuel efficiency and performance. It also allows for the rapid prototyping and iteration of new designs, which can help companies bring new products to market faster.

Architecture and Design

3D printing is also likely to have a significant impact on the architecture and design industries. Large-scale 3D printing could be used to create everything from furniture to entire buildings, while multi-material printing could be used to create complex, layered designs. This technology also allows for the rapid iteration of designs, which can help architects and designers refine their concepts.

Education and Research

Finally, 3D printing technology is likely to play an increasingly important role in education and research. This technology allows students and researchers to create physical models of concepts and designs, which can help them better understand and explore complex ideas. It also allows for the creation of customized tools and equipment, which can help researchers conduct experiments more efficiently and effectively.In conclusion, 3D printing technology and tools have come a long way, and their potential benefits are enormous. With continuous advances in 3D printing tools, it’s no exaggeration to say that the technology has the potential to transform various industries. With the knowledge gained from this article, individuals and businesses can better understand the possibilities of 3D printing tools and use them to their advantage.

FAQ

What are the most significant benefits of 3D printing?

3D printing has several benefits, including cost savings, speed in prototyping, the ability to make complex designs, customization, and reduced waste and environmental impact.

What materials can be used in 3D printing?

Materials used in 3D printing include plastics, metals, ceramics, and composites. The properties of these materials vary and can determine the suitability of their use for particular applications.

What are the best practices for using 3D printing tools?

Best practices for using 3D printing tools include proper software and hardware selection and maintenance, designing parts specifically for 3D printing, and optimizing post-processing techniques.

What are some of the emerging trends in 3D printing tool development?

Emerging trends in 3D printing tool development include multi-material 3D printing, large-scale 3D printing, and real-time, in-situ monitoring, and control.